Pressure vessels are most often used in domestic waterworks applications. Their main function is to balance and maintain a constant pressure in the water distribution system. They serve as water tanks and protect your pump from frequent switching, which could lead to rapid wear. Pressure vessels are most often made of steel and can be purchased in various sizes and volumes.

There are two types of pressure vessels - horizontal and vertical. Due to the size, large tanks are constructed with legs, which prevents the installation of horizontal containers (for example) in a vertical position. Installation other than the recommended may result in damage to the tank and loss of functionality. They are designed to apply pressure from top to bottom, so that if the installation is inverted, the pressure will be applied in a different direction than for which it was designed, and your vessel will be damaged.

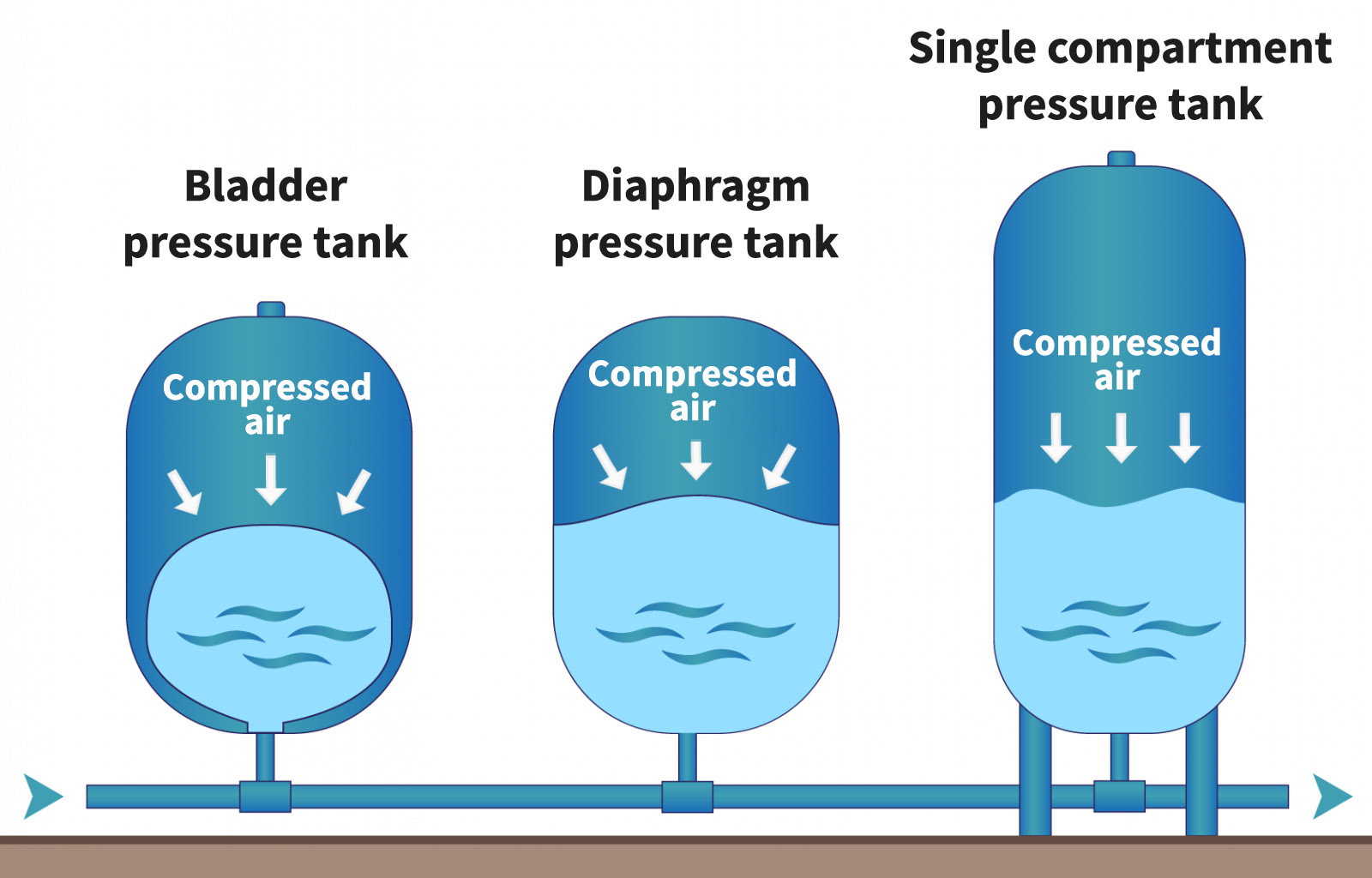

You can find three types of pressure vessels on the market, distinguished from each other by their internal arrangement and mean of operation:

Each type has its advantages and disadvantages, as we will demonstrate below.

A replaceable rubber bladder is located inside the vessel. The water flows into this bladder. There is a compressed air in the rest of the vessel, which ensures constant pressure in the distribution system. This air also protects the bladder from rubbing against the walls of the container. Thanks to the bladder, water and the walls of the container do not come into contact, so there is no risk of damaging the tank by corrosion. The disadvantage may be the need to check the overpressure in the vessel regularly, due to the possibility of air leakage. In the event of a leak, the air in the vessel would be reduced, which would switch the pump more often and more water would flow into the bladder. This would create a risk of the bladder tearing.

Each manufacturer defines the period of time after that it is necessary to check the overpressure. Adjusting the air is easy, it is done through a valve located on the vessel using an air compressor. If the bladder gets damaged, you can easily replace it without the need to replace the entire tank.

These vessels are also called maintenance-free because they do not require the internal compressed air to be checked at all as it has no way out of the tank. The vessel is divided into two parts by a rubber diaphragm, which separates water and compressed air. This type of container is highly reliable and durable, no inspections or maintenance are required, but unlike bladder tanks, the entire vessel must be replaced if the diaphragm gets damaged. This may sound inconvenient, but with no air escaping from the tank, the diaphragm is not overstressed and therefore chances of damage are low.

In this pressure vessel the water and air are not separated by anything. There is no risk of damage to any rubber parts and thanks to the stainless steel design it is suitable for humid environments. However compressed air in the tank must be checked regularly and the air must be replenished frequently as it drops.

The advantages of using pressure vessels in water distribution systems are, above all, prolonging the life of your pump and reducing the impact of hydraulic shocks on the system when the pump is started. Pumped water flows into the vessel where it compresses the air present. When the tap is opened (for example), the compressed air then pushes it into the pipe and overpressure in the vessel is reduced. If it falls below a certain level, the waterworks system starts the pump, which pumps water into the tank again. As air escapes from some vessels, the pumps may switch more frequently and shorten their service life.

If you wish to use the pressure vessel in drinking water distribution systems, we recommend that you check whether it has a drinking water certificate, which proves that the vessel is made of suitable materials that do not release any harmful substances.

There are several sizes of pressure vessels. To choose the right one, you will need to know your pump's parameters and the method of controlling the waterworks. But you can also make do with the volume of your water consumption over time. If you use water in different volumes and irregularly, it is better to buy a larger tank. However, be careful that is is not too large as the water would stand for too long and could "lose" its value. On the other hand, if you consume water in steady doses, a smaller tank is probably better. However, not so small as to cause your pump to run more often, which could again reduce its service life. In general, vessel with a volume of 80 to 100 liters are recommended for domestic waterworks. In the case of a waterworks with a frequency converter, which regulates the speed of the pump and ensures that its water pressure is constant, it is possible to omit the pressure vessel completely, or use only a small vessel.

You will find both complete domestic waterworks and separate pressure vessels and pumps on our site.