Can you help us with the website?

Don't worry, it's small text information that helps us evaluate the site or target relevant advertising. More about cookies here.

It will help us greatly if you enable everything. You can only enable the cookies you want. Alternatively, it is possible to disable everything except those strictly necessary for the functioning of the site.

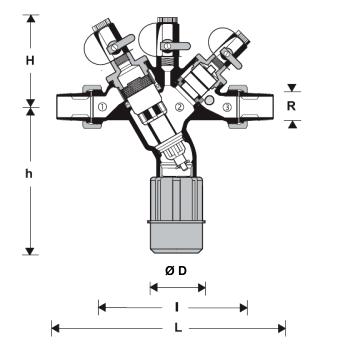

Backflow preventer protecting drinking water distribution from contamination to risk class 4 in accordance with EN1717. More information

Out of stock - can be requested

Would you like to get a price offer? Contact us

| Max. operating pressure | 10 bar |

| Max. water temperature | 65 °C |

| Medium | Drinking water |

| Weight | 7.10 kg |

The backflow preventer is suitable for residential buildings, industrial and commercial purposes. Protects drinking water systems against back pressure, back flow and back syphonage. This is most often used when combining water abstraction from the water line and boreholes.

Compact design with easy service and easy access to all internal components. The special design prevents water from "standing". The separator has a low pressure drop and high flow rate at a low noise level (approved by TUEV LGA group 1 without restriction). It is certified for use in drinking water and meets KTW and ACS recommendations for potable water

Construction

ConstructionBA type backflow preventers are divided into three pressure zones. The pressure in zone 1 is higher than in zone 2, which in turn is higher than in zone 3. A discharge valve is connected to zone 2 which opens at the latest when the differential pressure between zones 1 and 2 drops to 0.14 bar. The water from zone 2 discharges to atmosphere, both check valves close and therefore separate zone 2 from zone 1 and 3. In this way the danger of back pressure, back flow or back syphonage into the supply network is prevented.

We respond to your product queries as quickly as possible, usually within 24 hours.

Shopping with us

Personal collection of goods

Opening hours

Payment options

Delivery options

Contact

Copyright © 2024 BOLA spol s.r.o.

Bola.cz

Bola.cz

Didn't find what you wanted to know?