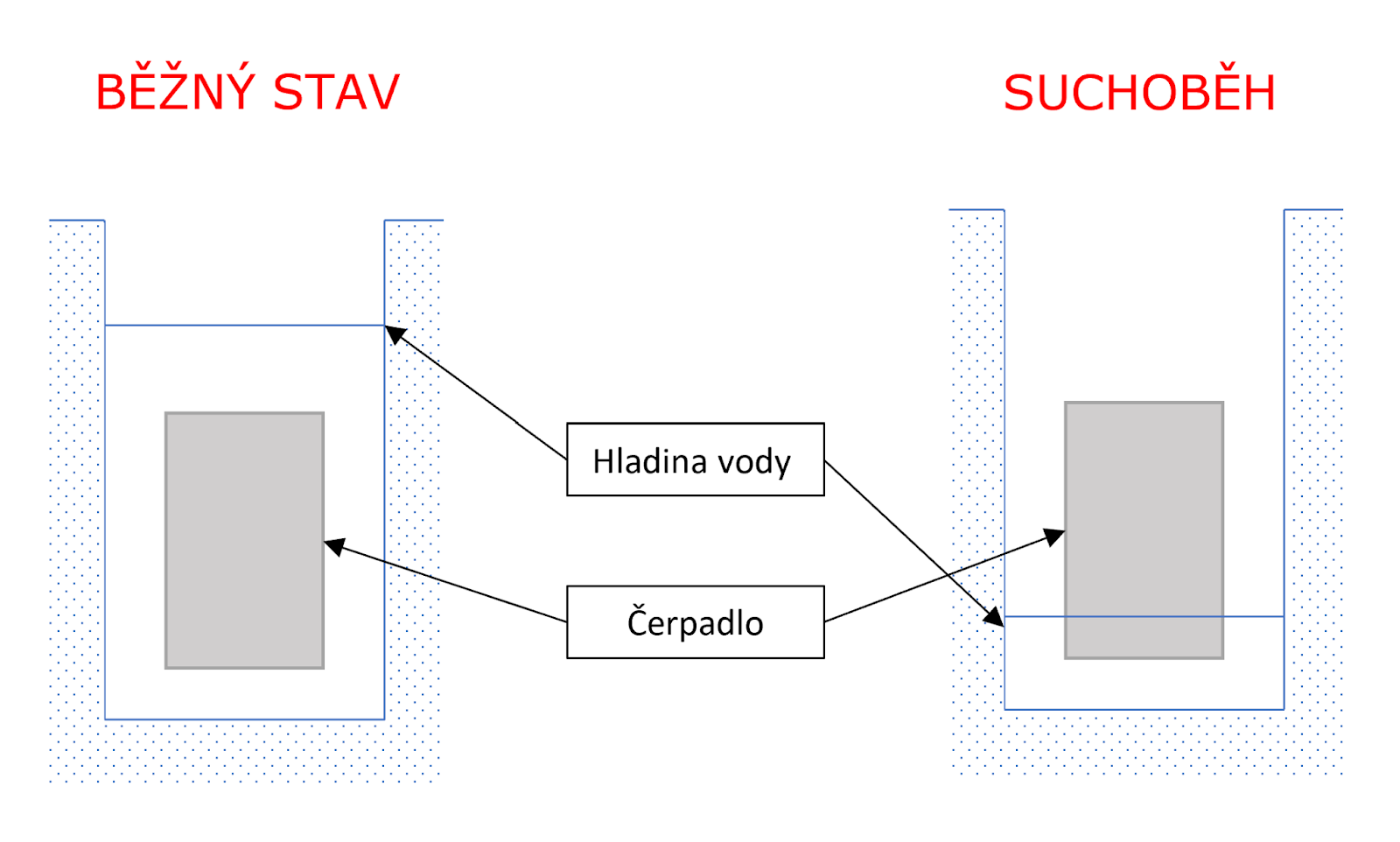

Submersible well pumps have high performance and are designed for continuous pumping of clean water from wells, boreholes, and collection tanks. A crucial condition for their proper functioning is that the well pumps are submerged in water below the dynamic level throughout their operation. Submersible pumps suck in water, which they then push up to the extraction point. The flow of surrounding water also ensures cooling of the pump and prevents motor overheating.

However, if there is not enough clean water in the well, the deep pump continues to run but without sufficient liquid. This condition is called dry running and can lead to complete destruction of the pump.

In the absence of water, the following undesirable effects can occur:

The pump draws contaminated groundwater, which may contain an excessive amount of solid matter. Well pumps are designed for pumping clean water: a higher content of abrasive particles and sandy material in the water increases pump wear, reduces efficiency, and significantly shortens the lifespan of the well pump. The contaminated water is further pushed up to the extraction points, however, it may additionally be hazardous to health. It is essential to clean the water well for subsequent pumping with a submersible pump .

The submersible water pump sucks in air or another gas from the surrounding soil. Bubbles form in the water, which substantially reduce the performance of the pump and their presence can lead to damage and complete destruction of the pump.

There is insufficient cooling of the submersible well pump. The flow of water around the well pump ensures its cooling. However, if there is no water in the water source, the pump cannot cool. This leads to a sharp increase in temperature of the submersible pump, which can lead to critical wear of the bearings and to burning and complete destruction of the motor.

Damage to well pumps due to dry running is one of the most common causes of pump failures, yet the investment in proper protection is negligible compared to the cost of a new pump. There are several technologies that ensure your pump turns off in time in case of low water level. Well pumps, however, have a specific construction, so not all dry-running protection methods can be used in this case.

In general, dry-running protection for submersible pumps can be solved in several ways, but when selecting a specific method, it is necessary to consider the conditions of the well where the pump protection will be installed.

So how to ensure protection against dry running?

Purchase a submersible well pump that already has built-in dry-running protection.

Installation of probes to monitor the water level in the well.

Mounting switches on the submersible pump.

Submersible pumps with a frequency converter, such as Grundfos SQ/SQE well pumps, have built-in protection against dry running.

Submersible well pumps monitor pressure through a control unit. If the water falls below the suction level, the pressure drops sharply. The frequency converter immediately recognizes the change and stops the motor before it can be damaged.

Grundfos SQ/SQE well pumps then automatically restart after five minutesbut will turn off again within five seconds if the water is still low, to prevent motor overheating. The whole process repeats until there is a sufficient amount of water in the source.

Switching Units for pump dry run protection are mounted directly on the submersible pump. This is an effective form of protection for standalone pumps that are not controlled by a control unit.

Float Switches represent a simple solution for monitoring water levels. The switch is connected to the pump in a basic position and when the water level drops, it tips over, thus turning off the pump. When the water level rises again, the pump starts up. The disadvantage of float switches is that sufficient space around the pump is needed for the float to move. In the case of narrow wells, installation is not possible.

Combined Switches monitor the adequate pressure and flow of the submersible pump. When a tap is opened (water drawn), the pressure decreases, which the combined switch responds to by turning on the pump. Once the water draw is finished, the switch detects the cessation of flow and the increase in pressure and turns off the pump. If there is not enough water in the well, the pump will not start, as the pressure and flow are not sufficient to draw water.

Water Level Monitoring using conductivity probes is a effective way to protect the pump from running dry. Probes monitor the amount of water in the source to prevent the water level from falling below the pump's suction level. Shutdown occurs before the critical depletion of water, and the pump remains submerged below the dynamic water level.

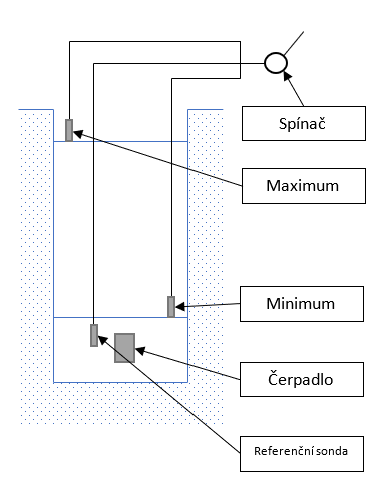

In a well, borehole, or tank, probes are installed to define from where to where the water should be pumped. The system works with just two probes, however, for optimal pump protection, three are needed: a probe for monitoring the minimum level, a probe for the maximum level, and a reference probe located below the minimum level. Once the water level drops to the minimum, the switch turns off the pump and restarts it when the water amount increases.

Conductivity probes have a wide range of applications and can be used for submersible and self-priming pumps. In the case of monitoring drinking water levels, it is essential to choose a type of probe that has the appropriate certification.

Diagram of level monitoring using probes

The most effective and reliable protection against dry running of the pump is not to leave anything to chance and ensure that excessive depletion of the water source does not occur. Frequent starting and stopping of the submersible pump in the well strains the motor and pump contacts and significantly shortens its lifespan, so it's good to prevent this problem. However, dry run protection systems are still a great helper, taking care of your pump and the entire well's protection.