Submersible pumps for boreholes are commonly used in boreholes and drilled wells for drinking water. They have a specific shape that allows them to be submerged into a borehole, but they also have high power required to draw water from great depths.

In recent years the demand for own drinking water sources has been rising. Independence meant mainly dug wells in the past. Currently, however, for example, due to surface water pollution, homeowners are increasingly leaning towards investing in drinking water boreholes. A specific subset of pumps with a small diameter and a specific elongated shape suitable for this application is used to pump clean drinking water from boreholes.

The diameter of the borehole is usually around 120 to 160 mm, and its depth can reach up to 300 meters, although depth of about 40 meters is more common. Your pump and its control system must also meet the specific conditions as well as the high demands on reliability. In extreme cases, incorrect installation or improper pumping can lead to clogging or even collapse of the borehole, which can mean a total devaluation of your investment.

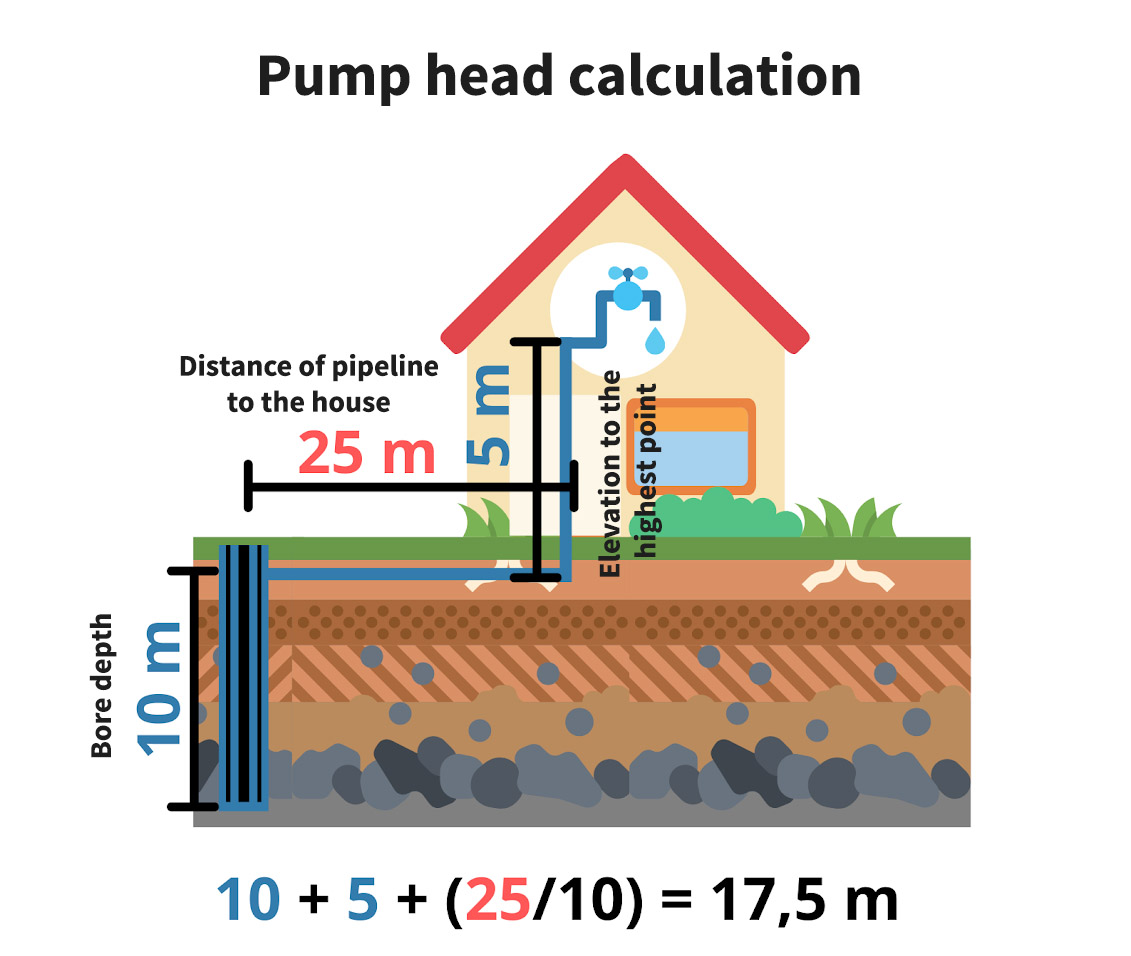

It is first necessary to calculate the appropriate pump head.

Key determinant is the calculation of the pump head. In simple terms, this value can be calculated as a sum of bore depth and elevation (height difference from the top of the bore to the highest point of discharge) and distance of pipeline from the pump to furthest point. However, distance of pipeline must be divided by ten.

Let's look at the example of a house that has the highest discharge point at a height of 5 meters. The bore, 10 m deep, is then 25 meters from the house.

Bore depth: 10 m

Highest point of discharge in the house: 5 m

Pipeline distance from borehole to the house: 25 m / 10 = 2,5 m

Pump head is in this case 17,5 m. After that it is necessary to verify whether the selected pump has a sufficient flow at this head - it should be around 3 m3 per hour.

There are two options. The first one is the purchase of a complete set from a proven manufacturer (our offer includes sets from Grundfos and Wilo), the second is the purchase of separate products, which in correct combination also ensure its function.

The easiest option are constant pressure maintaining sets, which are mainly represented by the Grundfos SQE, Wilo TWU and Wilo TWI series. These are complete sets which, thanks to the electronic speed control of the pump, enable power control according to set requirements. These sets contain a pump designed for continuous speed control, whose motor with permanent magnets is equipped with a stronger winding for higher durability. Sets also consist of a diaphragm pressure vessel, a pressure sensor and a shut-off valve with a manometer.

Control unit sensors thus get enough information to change quickly according to the power requirements. At the same time, the control unit monitors changes in a power factor cos Phi, which can indicate dry-running, and is equipped with overload protection. It also uses the slow start function, which reduces engine wear and reduces peaks of energy consumption, so lower-voltage circuit breakers are usually enough. The pumps also have an integrated check valve. However, when using the pump at great depths, we recommend installing another valve so that the high pressure does not break the one in the pump.

The second option is to purchase all the elements necessary for pumping separately. The key is the pump itself, for which you will also need additional switching unit such as a pressure switch and an expansion vessel, or a domestic waterworks set. The pump itself must be equipped with level monitoring system to protect it from dry running. It is also necessary to purchase a check valve so that the water above the pump does not damage it with its pressure.

We also recommend installation of a home cold water filter (for example Honeywell FF06-1AA), which protects your appliances from sand or dirt.

It is also necessary to know how to hang your pump in the bore. You can get stainless steel cables available from 15 m. With regard to the depth of the pump location and its power supply properties must also be calculated accurately, especially its cross-section. However, in many cases the cable is already included in the set.

Drilling will leave particles of sand and dirt inside the bore. First step is therefore to remove it from the borehole before connecting it to the house. Based on our long-term experience, we recommend using cheap and durable pumps (for example RUCHE), which will be used before the installation of the final product. Otherwise, these impurities can damage the impellers in the pump.

Yes. Borehole pumps can be placed vertically or horizontally. However, your pump must be equipped with a cooling jacket. It is a special device in a shape of a tube which function is to cover your pump. It is practically an imitation of a borehole. This type of pump requires water to swirl around it for proper cooling. If the well pump is placed in standing water, it may overheat and cause irreversible damage.